In the shadow of Capitol Hill, a forgotten patriot consigned to America’s trash heap of the unemployed has created a new national symbol that celebrates the values Sarah Palin holds true.

In the shadow of Capitol Hill, a forgotten patriot consigned to America’s trash heap of the unemployed has created a new national symbol that celebrates the values Sarah Palin holds true.

Starting in March 2010, the Ithaca Gun Company will begin shipment of a waterfowl pump gun that’s infused with a weather and scratch resistant treatment believed to be the second application of this formula for a civilian shotgun – the first coming with

Most shooters aren’t aware there is another shotshell manufacturer out there aside from the big four here in the United States. It’s RST and its has been around for a number of years. Their shotshells are manufactured in Friendsville, Pennsylvania, so they are not imported.

Down the hill, behind the old Jefferson County manor house, a six-point buck stood alert under the autumn sky. The dense trees put forward garden colors of carrots, raspberries, pumpkins and sweet peas. I rested against the stone wall. Traces of summer lingered with the few insects flitting around in the warm dusk. As the moon grew brighter I knew Prospect Hall would justly serve the Holland & Holland Royal in the trunk of my car.

Most people call it the SHOT Show. We think of it as Shotgun Candyland.

The Shooting, Hunting, Outdoor Trade Show and Conference (SHOT Show) is the largest and most comprehensive trade show for all professionals involved with the shooting sports and hunting industries. You’ll find plenty of so-called black guns for the tactical market, state-of-the-art bows, ammunition, a boatload of pistols and just about every conceivable gadget and gear on the planet for the hunting and shooting enthusiast as well as tools of the trade for the police and military.

The SHOT Show is also the best possible place to find shotguns for wing and clays shooting all under one roof. The giants of the industry such as Beretta, Browning, Winchester and Remington set aside sections in their massive exhibits for over/unders, semi-autos and side by sides.

They are accompanied by smaller companies with devoted followings such as Blaser, Fausti, Zoli, Ithaca, Caesar Guerini, Connecticut Shotgun, Benelli, Franchi, Stoeger and others.

The SHOT Show kicks off every year with Media Day. This gives the firearms press the opportunity to shoot just about every type of gun at a range. We flew in a day before the show actually started to participate in Media Day, giving us the opportunity to evaluate some new shotguns and perennial favorites. In a moment, we’ll share our impressions with you of a day on the range with these shotguns.

This year’s SHOT Show returned to Las Vegas from Orlando, where it was held in 2009. The SHOT Show packed the Sands Expo & Convention Center from January 19th through the 22nd.

The shows’ sponsor and owner, the National Shooting Sports Foundation, said that overall attendance reached 58,444, approaching the all-time record of the 2008 Las Vegas Show and approximately 11,000 more than last year’s show in Orlando. The 1,804 media professionals in attendance also set a new high. Exhibiting companies numbered 1,633 across some 700,000 net square feet in the convention center’s halls and the Venetian Hotel’s meeting rooms.

Whether you were on the show floor, the press room or the Media Day shooting ranges, you could hear languages spoken from Europe and Asia. At the Desert Sportsman’s Club, a group of reporters in front of me started speaking in German before switching to French when a fellow writer joined them.

The Desert Sportsman’s Club in Las Vegas hosted the 2010 New Product Event. Among the gun makers participating, we focused on shotguns provided by Browning and Winchester. About eight stands were lined up with some seven trap machines in what turned out to be a shooting free-for-all.

Winchester’s Super X3 Flanigan Exhibition/Sporting semi-auto just begged to be shot. With its candy-apple red receiver and matching forend cap contrasted against the black Dura-Touch Armor Coating, the 12 gauge simply dazzled.

Exhibition shooter Patrick Flanigan has set some speed records with a modified X3 so expectations ran high for performance. The shotgun proved to be fast, but for some inexplicable reason Winchester literally cut corners on the trigger blade. The sharp, perpendicular edges hurt your trigger finger and made the gun unpleasant to shoot. It was a far cry from the Blaser F3 28 gauge we’re currently testing, which has perfect ergonomics.

At $1,479, the X3 Flanigan Exhibition is about one-quarter the price of the Blaser F3. Still, there’s no excuse to fit a shotgun with a trigger that cuts into your finger.

We also shot Winchester’s Super X Pump Black Shadow. The action on this one was very smooth, but once again the trigger edges were angular. In addition to the trigger being painful, it was stiff and heavy – far more so than the prototype Ithaca Model 37 Waterfowl Model we had shot just a few days before on a sea-duck hunt (we’ll give you the exclusive story on that shotgun shortly).

After the two Winchester shotguns we moved on to the Brownings.

We tried the Browning Maxus semi-auto. Introduced last year as the world’s most reliable shotgun, the two 12-gauge versions we shot both jammed on the second shot. One of them featured the Mossy Oak finish, while the other was black. We certainly would have expected more.

Next, we shot the Browning 12-gauge 625 Citori over/under. It delivered on Browning’s reputation for quality and value. The shotgun had low recoil and a good finish. The 625 felt solid, the way Brownings are supposed to, and the gun shot well.

We picked up a .410 version of the 625. It proved to be a stunning clays crusher. Weighing slightly over 7 pounds, it delivered the handling of a bigger bore shotgun with the sheer exhilaration you can only get from a .410.

Our favorite shotgun at the Desert Sportsman’s Club, however, turned out to be a 28-gauge Browning Cynergy Classic. From an aesthetics perspective, we always did like the angled lines of the Cynergy receiver where it meets the stock. Plus the Cynergy receiver has a much lower profile than the Citori. Overall, it’s a more elegant, modern looking shotgun. This 28-gauge was extremely accurate – allowing us to break the targets and many of the pieces. With a suggested retail price of $3,509, you would be hard-pressed to find a better 28 gauge for the money.

Next stop was the Boulder City Rifle and Pistol Range for Bass Pro Shops’ Media Day. Nearly every type of gun was available to the press, but we made a bee line to the shooting ranges of Blaser, Ithaca and Beretta.

Just for kicks, Blaser gave demonstrations of a muzzle loader, which broke targets with authority.

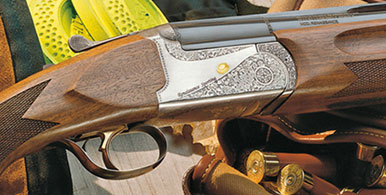

Beretta let us shoot a 12-gauge SV-10 Prevail. This handsome over/under benefits from state-of-the-art innovation that touches everything from the extractors to the hinges to the Kick Off anti-recoil on the butt of the stock. Once we located the point of impact and relaxed into the SV-10 Prevail, the gun proved nimble and easy to shoot, but we were disappointed in that it was difficult to crack open. These guns retail for about $3,000 and we can only assume opening the gun becomes easier over time. Otherwise, it would be a real challenge to buy a more advanced over/under at that price.

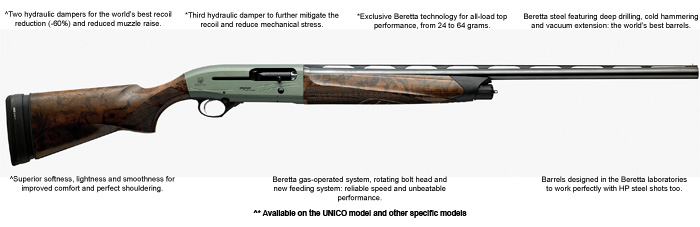

Also available to shoot was Beretta’s latest semi-auto, the A400 Xplor Unico, 12 gauge with the Kick Off recoil-reduction system. Officially unveiled at the SHOT Show, this gun is distinguished by the Unico chamber, which reliably accepts shells ranging in length from 2 ¾ to 3 ½ inches. The rotating bolt with reinforced lugs is flexible enough to manage the different shells while at the same time reduces time between cleanings and improving cycling time by some 30 percent. Weighing in at a scant 6½ pounds, it’s among the lightest semi-auto on the markets.

We found that we had to float the targets over the front bead to break the outgoers thrown from the single trap machine. The Kick Off worked as advertised, especially given the shotgun’s bantam weight. The A400 Xplor Unico shouldered fast and handled well. Priced at $1,725, it’s about $500 less than Beretta’s preceding flagship semi-auto, the 391 Technys Gold Sporting.

We wrapped up our Media Day shooting with the extraordinary Ithaca 12-gauge over/under Phoenix. The last time we shot it, the gun was in the prototype stage and we declared it the softest shooting 12-gauge over/under on the planet. Now several months later, the Phoenix was even tighter. The latest iteration of the gun shot so straight I’m convinced that even a blind folded shooter could crush targets with it. The Phoenix is in the final stages of refinement and we could see the first models come out of the factory this summer. If you’re interested, get your deposit in early because the Phoenix is already back-ordered.

Shotgun manufacturers took the opportunity to introduce several new models at the SHOT Show.

Franchi brought out a Renaissance Sport over/under in a 20-gauge. The coin-finished receiver includes ornate scroll work while the oil-finished stock is made of A Grade walnut. The suggested retail price is $2,349.

Winchester introduced the Walnut SX3 20 gauge at a starting price of $1,199. The All-Purpose Field model in 12 gauge is now available with a new Mossy Oak Break-Up Infinity Camo finish for $1,469.

CZ USA, the American arm of the Czech gun maker, brought out a new ultralight 12-gauge over/under called the Upland Ultralight. Its light alloy receiver brings down the weight to 6 pounds – 2 pounds lighter than the steel-frame versions. The new shotgun starts at $749.

Weatherby expanded its SA-08 line with two new models: the Deluxe and Waterfowler. The Deluxe features a high-gloss walnut stock and blued metalwork. It’s available in both 12- and 20-gauges models for $739. The Waterfowler has a camo synthetic stock and is only available in 12 gauge. It sells for $699.

We’re already looking forward to next year’s SHOT Show, to be held at the same venue on January 18-21. Stay tuned.

Irwin Greenstein is the Publisher of Shotgun Life. You can contact him at contact@shotgunlife.com.

Useful Resources

{loadposition signup}

On the used gun market the most valuable, discontinued Browning – the Superposed over and unders – are those in 28 gauge. But .410 Superposed over and unders are not far behind in price.

Interestingly, there were more .410s produced in the Superposed than in 28 gauge. Further, the most valuable of the Superposed guns are the higher grades. There were quite a number of different higher grade Superposed over and unders, but we know them best as the Pigeon, the Pointer, the Diana and the Midas – with the Grade I being the lowest priced of these guns. Even the Grade I owned was very nice with its deep-cut engraving. But if you have a 28 or a .410 in Pigeon, Pointer, Diana or Midas Grade you certainly have a shotgun that’s worth plenty.

So I’m wondering if the Citori over and unders, especially those in the higher grades and in the smaller gauges, are destined to increase in value over time. The high-grade Citoris being offered by Browning are currently the Grade IV and the Grade VII. Like the 20, 28 and .410 Superposed, the small gauge Citoris are built on a 20-gauge frame. The Citori I’ve been shooting up a figurative storm with is the .410 Citori Grade VII with 28-inch barrels. More about shooting that gun shortly.

The three small-gauge Grade IVs are intricately engraved – including game scenes of flushing quail on the left side of the receiver, a flushing ruffed grouse on the right. To my eye this engraving is extremely well executed.

The Grade VII is also intricately engraved all around the game scenes – with three flushing grouse in gold on the left of the receiver, three flushing quail in gold on the right. The birds are well rendered, but it’s all the surrounding engraving that really catches my eye.

On the head of a pointer in gold on the bottom of these receivers, that gold head is surrounded by one heck of a lot of very intricate engraving. There’s also intricate engraving on the fore-end iron, the barrel “wings,” the receiver fences, the opening lever, top tang and trigger guard. This isn’t “just” engraving, as it’s very intricate and special, and the workmanship makes me wonder what these guns are going to be worth 60 – 80 years from now.

I realize (and probably so do you) that most of today’s engraving starts out with some type of chemical or etching process, but then that resultant engraving is worked on extensively by hand – by experts. For most of us, the days are over for real hand engraving with no help from acids, chemicals or whatever.

If a master engraver works for four months engraving one gun he is probably going to want about $40,000 – and that’s just for the engraving. The price of the gun itself is not included. So I’m guessing that the only shooter who can afford $40,000 worth of engraving has to make about $400,000 in four months. Along those same lines, if it takes a master engraver a year to make a super fine piece he’s going to want about $100,000 these days. The only folks able to afford that much money certainly have to make two million a year or more. That’s why I say true hand engraving has gone beyond most of us.

However, the engraving on production shotguns these days is sometimes outstanding – at least on some of the shotguns I’ve examined over the last several years. Today’s Grade VII Brownings are engraved so well that anyone examining these guns will be very impressed.

The Citori Grade VII .410 I have been shooting is the Lightning. Of all the various Citori models the Lightning is my favorite. I no doubt favor this model because of the stock’s lines – the semi-open pistol grip and the Lightning-style fore-end – which is rounded on the end.

The name “Lightning” and the style of the stock were stolen from the Superposed Lightning model. Browning was very wise to put this model in the Citori line as the Superposed Lightning was not only one of the best sellers – the Superposed Lightning is also very much sought after in the used market.

With the Grade VII you obviously get a very nice piece of walnut for the stock and fore-end. Further, the checkering is not only perfectly done – it’s tight at 20 lines-to-the-inch. The trigger is gold plated. In all three small gauges the Lightning wears a plastic butt pad so you will never have any gun mounting problems due to a sticky pad. The vent rib sits reasonably high, a good thing for hopefully preventing too much head lifting at trigger-pulling time. That rib is slightly tapered on the small gauge guns – .270 at the breech – .245 at the muzzle. Three screw chokes are included in all three gauges (even the .410): improved cylinder, modified and full. Also, it would be nice if Browning supplied at least one, preferably two, skeet chokes.

Because of the 20-gauge receiver, this Grade VII Lightning .410 is lightweight It weighed in at 7 pounds, 2½ ounces with 28-inch barrels (26-inch barrels are also available).

With my Baker Barrel Reader I measured the top barrel at .411, the bottom at .410. The improved cylinder measured .405, the modified .400 and the full went .395. The fore-end weighed 14.9 ounces and the barrels, 2 pounds 15 ounces.

Using my Shotgun Combo Gauge I measured the length of pull at 14 3/8 inches, the drop at comb 1½ inches, the drop at heel at 2 ¼ inches, and the gun balanced right on the hinge pin.

While serious competition skeet and sporting are great (I know a lot of you don’t shoot competition) just shooting for the fun of it is what I do these days. Accordingly, I have never met a real shooter who did not love shooting the .410. With that gun’s minimal recoil and impressive breaks at short ranges – using the proper chokes – what’s not to love about shooting a .410?

Although all the Lightning model .410s have 3-inch chambers (great for hunting), my clay target fun has been with the 2 ½-inch, ½-ounce rounds. For this shooting the Grade VII is pure joy, plus the 28-inch barrels swing well; and because of the 20-gauge receiver and the gun’s resultant weight of 7 pounds 2½ ounces there’s essentially no recoil at all.

The .410s that are really light, like under 5 pounds or a bit over 5 pounds, have more recoil than with this heavier Browning. Not that the recoil is bad in a 5 ½ pound, .410 shooting 2 ½-inch shells; it’s just that the recoil is even less with this Browning I’ve been having fun with. Another benefit to the heavier .410 is that this Browning .410 swings great compared to a 5 ½ pound .410.

To simulate upland bird flushes – the likes of ruffed grouse, woodcock and quail – I do a lot of this fun practice shooting from a low-gun position on stations six and two on a skeet field. These quartering away targets are often seen in hunting situations. But I also shoot plenty of low seven and low five targets, which also simulate certain upland bird shots.

Despite opinions by some, the .410 can be a good hunting gun as long as the shooter restricts the range. When I hunt with a .410 I go to the 3-inch shells. In addition to close-flushing upland birds, the .410 is also ideal for dove shooting, especially if the birds can be shot within the .410’s comfort zone. To simulate practice for this gunning I like to call for the bird from a low gun position, taking quartering incomers from stations one, two, six and seven, and full crossing shots from stations three, four and five.

Is this Grade VII Citori a shotgun that will gain in value as the decades pass by? There’s no guarantee of that, just the guarantee of one heck of a lot of shooting fun – speculative financial hopes be darned. With a suggested retail $5,109, this .410 is great fun to shoot today and could make for a lasting heirloom.

Nick Sisley has been a full-time freelance outdoor writer since 1969. He writes a regular shotgun column in Wildfowl magazine, Sporting Clays magazine, the Skeet Shooting Review and others. He’s authored eight books and penned thousands of magazine articles. He can be contacted at nicksisley@hotmail.com.

Helpful resources:

{loadposition signup}

A research team at Remington has developed a revolutionary new wad design that lets steel shot fulfill its long-promised potential as the ultimate waterfowl load.

For waterfowl hunting, steel shot is the odds-on favorite. Other non-toxics are available, and most all of them result in better performance than steel. But these other non-toxic waterfowl loads are not purchased in huge quantities for one basic reason – they are more expensive than steel loads – a lot more expensive.

If you shot any of the early steel loads from several decades back you know those loads were very poor. They shot horrible patterns, produced a lot of powder fouling, and maybe crippled more ducks than the lead pellets that ducks ingested. Slowly the shotshell manufacturers improved on the steel loads. One factor that helped this along was new powders designed with steel in mind. This resulted in less powder fouling. Those who shot semi-auto shotguns at ducks cheered this breakthrough as this meant their shotguns now kept shooting instead of jamming so often.

Another factor that helped steel loads kill ducks more effectively was that the ammo companies were able to increase velocities with the new powders. Since steel is less dense than lead (lighter by 30 percent), the increased velocity helped steel enhance its killing power.

However, current steel loads are at their maximum – both from a velocity standpoint and from a chamber pressure standpoint. In fact, most high velocity steel loads produce chamber pressures that are right at the top of what experts consider safe. Increase chamber pressures further and we increase the chance of starting to blow up some shotguns. No ammo company is going to do that in these sue-happy times.

So how can we (1) reduce chamber pressures and still keep velocity of steel loads at current levels, and/or (2) increase steel shot velocity levels – and still keep chamber pressures within proper safety standards?

A research team at Remington went to work on this problem, and they have come up with a solution that promises to be a major breakthrough in shotgun ballistics – not only for steel shot but lead loads as well – in fact maybe all future shotshells.

Remington developed a totally new concept in a plastic wad that makes all of the above possible. The wad design is so new that we don’t even have any new loads to test – that have these wads installed. Remington is so confident in this wad’s potential that they are calling this the biggest breakthrough since the introduction of the plastic wad itself.

Remington had a name for this wad, but they have pulled that name back in hopes of a better one. Maybe now you’re getting some appreciation of how new this technology really is.

Check the accompanying artist’s rendition of this wad. The main breakthrough is the precision engineered “ignition chamber,” the smaller cylindrical part at the base of the wad. This ignition chamber is designed to nestle into the top of the primer pocket.

The powder is dropped in a normal manner. When the new wad is seated some of that powder works its way into the ignition chamber. To insure that powder fills that ignition chamber a ball-type powder with tiny grains will be used. Now remember that the ignition chamber is sitting right on top of the primer.

When the primer is ignited the small amount of powder in the ignition chamber gets ignited first, thus the burn is started. In turn, the wad and shot column move slightly forward, and this allows the burning powder in the ignition chamber to ignite the rest of the powder charge.

How can this reduce chamber pressures? It’s all about delaying (slowing down) full ignition of the powder. Use of the new wad system means that powder ignition is stretched out over a longer period of time – and that’s how chamber pressures are reduced. Bottom line – these researchers had to think out of the box to come up with a new way to reduce chamber pressures.

While I like the idea of the new wad for reducing chamber pressures in steel shot loads – I’m thinking to the future – and hopefully building this wad technology into target loads and field loads using lead shot. Being a recoil conscious freak I’m hoping the new wad will reduce felt recoil in target loads – via reduced chamber pressures – but still maintaining standard target load velocities.

Remington says they will be using slow-burning ball-type powders with the new wad and their new steel loads. I know of no current slow burning ball powders available to reloaders, but evidently Remington has worked with a powder manufacturer to develop such a powder.

An example of a slow burning powder and the resultant reduction of felt recoil would be reloading with slow burning IMR 7625 powder to develop an 1150-feet-per- second load with 1 ounce of shot in 12 gauge.

Work up the same 1-ounce, 1150-feet-per-second load using a fast burning powder, and it won’t take any rocket science research to feel that the 7625 load is very soft in comparison. Of course, 7625 is not offered in a ball-type configuration, but I can only assume that the science to do that is doable. The same principal that allows a slow burning powder like 7625 to have less chamber pressure – is now offered via a wad – a wad that slows down the burn rate and results in lower chamber pressure – and lower chamber pressures mean less felt recoil – a gentle shove rather than a sharp rap.

Remember – as the ignition chamber powder ignites the wad and shot charge move slightly forward – increasing the area for the rest of the powder burn – and thus we get the slower powder burn – ignition stretched out over a longer period of time.

A second new feature of breakthrough wad will be the “stress concentrators” built in near this wad’s base. Again, check the artist’s rendition. The new wad is not split down the sides, as most all other wads are. The “stress concentrator” areas, however, start the wad slits upon powder ignition. There are internal “slits” inside this wad, making it easy for the stress concentrators to start and complete the wad slitting up the sides. But because the slits start opening from the bottom, the pellets in the wad are held there longer, which Remington says results in tighter down range patterns.

Initially, (which means Fall 2010) Remington will only offer the new shotshells with the new wad in 12 gauge and in steel 3-inch and 3 ½-inch loads. All these loads will be at the same velocity – a whopping 1700 feet per second – which means no lead changes no matter which of these loads you are using.

Remington is calling the new shells HyperSonic Steel™. Interestingly 1 1/8, 1 1/4 and 1 3/8 ounce loads will be offered in the HyperSonic Steel – again all at 1700 feet per second. The 3-inch 1 1/8 ounce loads will be offered in BB, 2 and 4. The 3-inch 1 1/4 ounce loads will be offered in BB, 1, 2 and 4. The 3 ½-inch HyperSonic Steel will be offered in BB, 2 and 4 at 1 3/8 ounce.

As much as I’m excited about these new steel loads with the new wad I’m looking farther into the future – and lead target and field loads that utilize this new wad technology that permits slower burn rates with resultant lower chamber pressures and less felt recoil.

If a slow burning powder like 7625 in ball form could be used with this new wad chamber pressures could be reduced even further. Think of shooting a 1-ounce 12-gauge load at 1200-feet-per-second that results in even less recoil than we see today using slow burning 7625. The 7625 is used only as an example here, for there are other slow burning powders, though when it comes to 12 gauge shotshell powders IMR 7625 is one of the slowest.

I predict you are going to be hearing a lot more about this new wad design, and this wad could be the biggest advancement since the development of the plastic wad – especially if the wad technology can also be applied to lead loads.

Nick Sisley has been a full-time freelance outdoor writer since 1969. He writes a regular shotgun column in Wildfowl magazine, Sporting Clays magazine, the Skeet Shooting Review and others. He’s authored eight books and penned thousands of magazine articles. He can be contacted at nicksisley@hotmail.com.

Remington Ballistics:

http://www.remington.com/products/ammunition/ballistics

{loadposition signup}

There are no signs on the factory at 420 North Walpole Street in Upper Sandusky, Ohio, but open the old door and the pungent smell of machine oil is your first hint that the Ithaca shotgun is being re-born.

This rambling building that once housed a rolling rink, an automotive center and mold-making operation has been transformed into the backbone of the Ithaca Gun Company. Hard-working American men and women, like so many discarded in the upheaval of globalization, are now devoting their full measure of sweat and muscle to manufacture a new 100-percent American-built over/under shotgun code-named Phoenix.

“It’s nice to think that we could help our brothers and sisters in America by keeping and creating new jobs,” said Ithaca machinist, Tom Troiano.

Every screw, spring and steel billet is sourced from the U.S. as the company brings to life the stunning new 12-gauge Phoenix. From its inception, the Phoenix was designed to honor the proportions and sturdy sensibility of the classical over/under American shotgun.

Shotgun Life recently enjoyed the privilege of spending a full day at Ithaca talking with nearly everyone in the company. We spoke with the men who made the barrels, the receivers and the stocks. We spent time with management. And we were given the unique opportunity to be the first one outside of the company to shoot a prototype of the forthcoming Phoenix.

We can report unequivocally that design breakthroughs engineered into the Phoenix have made it the softest shooting 12-gauge over-under we have ever pulled a trigger on. The felt recoil on the Phoenix is virtually nonexistent – on par with the benchmark Beretta 391 Target Gold 12-gauge semi-auto – kicking only just enough to reset the inertia trigger.

Better yet, with a starting price of about $2,500 and moving to $10,000 depending on the type of engraving and grade of American walnut, the Phoenix could easily mark a renaissance of the big Ithaca shotguns.

That’s why Ithaca named the Phoenix after the dazzling mythical bird which rose from the ashes to fly once again. But leading Ithaca authority, Walt Snyder, author of the definitive books The Ithaca Company From the Beginning and Ithaca Featherlight Repeaters…The Best Gun Going observed that the new Phoenix also has an historical precedence.

In 1945, Ithaca had built a one-of-a-kind 12-gauge, over/under prototype. As the Model 51, it had serial number EX1, for experimental 1. It now appears that the new Phoenix is a direct descendant of that orphaned masterpiece.

Our first glimpse of the new 12-gauge over/under took place in January 2009 at the expansive Shot Show. There in booth 1736, I was drawn to the allure of an elegantly understated over/under that was all chrome-moly black steel and American walnut. The receiver, devoid of engraving, drew me in and I picked up the gun. I mounted it to my shoulder, my immediate impression one of a tight, well-balanced shotgun. Then I moved the top lever to the right and to my astonishment the barrels slowly fell open as though on hydraulics.

This was the shotgun that Walt would see several months later at a dealer event in Wilmington, North Carolina. Ithaca’s Mike Farrell arrived with it and Walt’s initial impression was that “It looked like a very well made gun. It seemed to mount and balance very well.”

At the time of the Shot Show, the gun remained months away from being in shooting condition and it hadn’t been christened the Phoenix. But after returning to the office, I would occasionally call Mike, the company’s number-two guy (no one at Ithaca has a job title), until he agreed to let me visit the company and actually try the shotgun.

For those of you familiar with Ithaca shotguns, it would be easy to dismiss the Phoenix as another heartfelt effort to salvage this fabled American manufacturer established in 1883.

Taking its namesake from the first factory in Ithaca, New York, the company’s fortunes in later years have been a tortured tale of missteps as one management team after another tried to reclaim the glory years that spanned the late 1800s until Pearl Harbor. That was a triumphant epoch when Ithaca manufactured shotguns such as the Flues side-by-side, the Knick trap gun, the 3½-inch Magnum 10 and the Model 37 pump based on a design by John Browning.

Beginning in the late 1960s, the company changed hands several times until it padlocked the doors in1986. The following year a new investor group took the helm until 1996, when entrepreneur Steven Lamboy acquired the assets and rights to make the Ithaca doubles. He turned out some beautiful shotguns in Italy bearing the Ithaca name but fell into bankruptcy in 2003. By 2004, the Federal government attached the company’s bank accounts for back taxes and a bitter lawsuit ensued in New York state between various stakeholders. In 2005, Ithaca’s assets were surrendered and the company liquidated.

That’s when Craig Marshall entered. Owner of MoldCraft in Upper Sandusky, he converted the family mold-making business into a new iteration of Ithaca. During the transition, the Marshalls assembled the flagship Model 37 pumps from existing inventory with every intention of restoring the marque’s luster. Unfortunately, the Marshalls eventually found themselves under-capitalized for the venture to the extent that they were forced to idle the factory for eight months between 2006 and 2007.

Finally, in June 2007 industrial glass magnate David Dlubak acquired the company’s assets and Ithaca name from the Marshalls. He started making fresh plant investments in the nondescript Upper Sandusky facility and brought back the team working on the Model 37.

As Dave explained to us in Ithaca’s distinctly blue-collar conference room, “We want to make a high-quality shotgun, at an affordable price, that will fit in the working man’s hands. The gun is going to be that guy’s pride and joy. The old Ithacas lasted fifty or sixty years. Now we make them to tighter tolerances and with better steel. We don’t want cheaper, we want better.”

Like many luminaries in the industry, Dave did not get his start making shotguns. Just as Harris John Holland began as a tobacconist, and Charles Parker a maker of spoons, curtains and locks, Dave comes from a family that owns and operates one of the largest industrial glass recycling businesses in the U.S., Dlubak Glass.

Dave was in the process of finalizing a new product called “bubble glass” that combined concrete and glass in faux log building material. Replete with grains and knots, bubble glass is resistant to fire and insects but soft enough for an ordinary drill bit. He was looking for a mold maker who could package the bubble-glass logs for affordable and dependable shipment.

He went to MoldCraft and met the Marshalls. Dave was presented with an opportunity to invest in Ithaca. Instead, he bought it.

Although a long-time aficionado of Ithaca shotguns, he acquired the company because of “the quality of the people and their ability.” These tool-and-die makers were the “elite of the elite,” he said.

For example, barrel-maker Roger Larrabee has been a tool-and-die machinist for 47 years. He trained Tom Troiano, who turns out the receivers.

“Roger trained a lot of the guys here,” Tom said.

As a self-described “control freak” with a passion for quality, it was paramount for Dave to build a team with the capabilities to “make all the parts here,” he said. “I’m interested in making it all under one roof.”

He characterizes the Ithaca Gun Company as being in “stage two,” meaning that it has resolved the manufacturing issues with its current popular pump guns: the accurate Deerslayer series, the rugged Model 37 Defense, and the sweethearts of the pump-gun community, the 28-gauge Model 37 and the Model 37 Featherlight and Ultralight.

These shotguns showcased the production capabilities of the company. They demonstrated the team’s ability to craft receivers from a billet of steel or aluminum, to do away with soldering or any other heat-inducing joining, and to machine one-piece barrels with integrated rib stanchions that eliminate any potential warpage from the run-of-the-mill rib soldering.

“Ithaca certainly seems to have manufacturing savvy,” Walt said. “I’ve seen their Model 37 and it’s beautiful and I would assume they would be successful with the new over/under.”

These accomplishments came from “spending many midnights sorting these things through,” Dave said. “We’re not in love with wood, we’re in love with steel.”

The company’s passion for steel is clear when you tour the factory floor. As raw Pittsburgh steel goes from the mill-turn lathes to to grinders to finishing machines to polishers there is an almost monastic sense of duty among the people making parts for the shotguns. All the tooling and fixturing was developed in-house. Custom software was written by the youngest guy on the crew for the tightest possible tolerances. The individual components are funneled into an assembly room where one person hand fits everything together into a single shotgun.

After the factory floor I spent time with Aaron Welch, Ithaca’s designer and engineer. Looking over his shoulder in the cramped office, he rotated the solid-block 3D models of the Phoenix on his computer monitor.

There was the Anson-Deeley boxlock action ready to fire 2¾ inch shells.

I discovered that a secret to the low recoil of the Phoenix are the three capsule-shaped pockets machined into the bottom of the receiver. They are designed to distribute the load of shooting, improve longevity of the components and help absorb the spent gasses. Moreover, the slightly greater mass of the receiver and monobloc combine to give the Phoenix a lower felt recoil. The less-restrictive 1.5 degree forcing cone and somewhat heavier burled stock also helped tame excessive kick.

In examining the monobloc, Aaron talked about how the barrels are held to the breech section by a tubular connector, instead of being soldered, to improve reliability. At the business end of the 30-inch barrels, the muzzles are dovetailed together, rather than soldered, to prevent distortion from thermal expansion.

That sense of a hydraulic assist when opening the shotgun comes from cocking rods that push against the hammer springs when you move the top lever.

The top bolting mechanism was borrowed from the old Ithaca Knick. It sits high in the receiver for a stronger grip on the monobloc.

Next I looked at how the rib slides into the stanchions and is mounted with a single screw. Aaron said that interchangeable ribs would be available to provide different points of impact.

In the end, the Phoenix would weigh about eight pounds.

Now it was time to see how all the parts worked together.

Mike grabbed the prototype of the 12-gauge Phoenix. The shotgun was still in-the-white with a couple thousand test rounds through it.

We drove a few minutes to a piece of property on a lake that had once been a quarry. A house overlooking it was under construction. The house belonged to Dave and was being built from bubble glass in cinder-block form factors.

In addition to the house and lake, the property also had a trap machine set up by the previous owners.

Mike handed me the gun and in fact it did feel very well balanced. I practiced mounting it a few times. The straight stock fit quite well. Dan Aubill, the guy in charge of Ithaca’s custom stock program, had told me that it was measured to fit the “average guy” with a 14¼ inch length of pull, zero cast, drop at comb of 1½ inch and drop at heel of 2¼ inch.

Pushing the top lever, the barrels slowly fell open. I loaded in two 1? ounce shells. Mike took up the controller and when I called “pull” two things immediately took me by surprise. The first was the extremely low recoil, the second is how I completely pulverized the targets.

Mike and I went through a couple of boxes of shells, the two of us taking turns pulling targets. The trigger was light and crisp, the beads lined up perfectly and the tapered forend enabled a wide range of control.

I turned out to be the last one who shot the Phoenix that day and when the time came to return it to Mike I thought “I gotta get one of these.”

Irwin Greenstein is the Publisher of Shotgun Life. Please send your comments to letters@shotgunlife.com.

Useful resources:

You probably already have some preconceived notions about your dream shotgun, and that is just fine. But sometimes it pays to seek advice from someone who has had literally hundreds of shotguns pass through their hands, had so many different stocks touch their cheek, fondled so many receivers. Lucky for me, I am one of those folks, so hopefully what I’m going to tell you might help with your future purchase.

What is the most important quality to seek in your next shotgun? A beautiful piece of walnut, out of this world engraving, strength to hold up to a million rounds, a stock that fits you perfectly? Or what? To me all these factors are important, as are others, but I think the best quality a shotgun can have is feel. That’s what to look for first.

It’s difficult to describe feel, just as it’s difficult to describe love at first sight. You just know both when you feel either. Once you love how a shotgun feels you are going to thoroughly enjoy it. You are going to have great confidence in it. After that you can always add such luxuries as a custom stock, custom engraving, custom checkering, whatever. But if you don’t start out loving the feel of a shotgun the cards are stacked against you ever shooting that gun all that well.

When it comes to semi-autos I think Beretta attained the feel I’m talking about with the models 303, the 390, and now the many versions of the 391. I don’t think it’s easy to incorporate a good-feeling quality into a semi, but I do believe Beretta has done it. It’s more than balance I’m talking about, but good balance is certainly a big part of having a shotgun feel right. A shotgun with great feel should move almost effortlessly to the target – pitch or feathered. Such a shotgun will probably let you think it actually weighs less than it really does. You should look forward to picking up and fondling such a shotgun every chance you get.

Have you ever picked up a Perazzi? If you have not done so I urge you to do that – do it even if you cannot afford one. There’s something about virtually every Perazzi I pick up that just sings feel. From the initial pick up to the shouldering to the mounting to the swinging, even to the sound of a Perazzi clicking shut – for many it is a love affair at first sight or first feel. This seems to be true no matter the barrel length for this company has a way of matching barrel weights to the receiver, stock and fore-end so that balance and feel are not compromised. To experience feel first hand just pick up and handle a Perazzi intended for field shooting – or one of their sporting clays models.

The English got feel right over 100 years ago – with their side by side shotguns, first with hammer guns, but later with sidelocks and then even boxlocks. Not many of us are going to have the opportunity to pick up, fondle and swing a Purdey or a Boss, but maybe one day you will have a chance to do this with one of the lesser known old English doubles – perhaps an Army & Navy, a Webley Scott (this company made many fine English double guns sold in other names), a Cogswell & Harrison, a Reilly or one from a number of other English makers that don’t bring the prices of a Purdey, a Holland or several others. If you ever get the chance to handle a gun like this you will see what I mean by feel.

Enough about feel – let’s move to fit. Whatever new gun you buy – it probably won’t fit you perfectly. However, this does not mean you have to change the beautiful stock the gun came with – at least hopefully not. Length of pull can be adjusted with a thicker or thinner recoil pad. If the comb is too high you or a stock person can sand away until that portion of the fit is correct, and then minimal refinishing could be all you need to fix the looks of the walnut.

You could also have the stock you buy made into an adjustable comb stock – or it may come with one. These are sort of ugly but not double ugly. You could add self-adhesive Moleskin (available at drugstores) to the comb if the stock is too low – sort of double ugly but serviceable.

The best way to determine gun fit is to have a pattern paper or steel plate to shoot at. The premise should be to shoot over and over – say at least five times – at the same pointing spot on the paper or the steel plate. Is your new gun shooting high, low, left, right or some combination of two of those? No aiming for this work. Just pull the gun up and shoot.

Don’t overlook the recoil pad. Sad to say some recoil pads put on factory shotguns these days are abominable. This is not to say such pads don’t have recoil-absorbing qualities. That’s not what I’m getting at here. A recoil pad should be a significant aid in helping with a perfect gun mount. Too many pads are a significant handicap in allowing the shooter to make a great gun mount. With some pads the consistency is simply too sticky. Those that are cause a lot of gun mounting problems. Another problem is caused by sharp pad edges, especially at the top of the pad. Consider the type of pad that has a plastic insert at the top – a feature that can be a big factor in reducing gun mounting hang ups. Further, rounded edges all around the pad help guard against sharp edges gouging into the shoulder area. The recoil pad is perhaps the most overlooked aspect of new or used shotgun buying. Of course, the buyer can always add the recoil pad of his or her choice after purchase.

For hunting, as opposed to competition shooting, I actually like most shotguns fitted with either a plastic butt plate or simply a checkered butt. These are hunting guns, most of which are shot minimally, as opposed to competition guns which are shot one heck of a lot. With a hunting gun the plastic butt pad or checkered butt stock tends to reduce back-end weight a tad – and certainly facilitates an easy, unobstructed gun mount.

In wrap up I will make one additional shotgun make suggestion for you to consider picking up, shouldering and swinging at the gun shop. This would be the Caesar Guerini, and the company makes many models, those for hunting, skeet, trap and sporting clays. This company goes to special pains to make the guns balance just ahead of the hinge pins or trunnions – and they do this regardless of barrel length. To me all the Guerini over and unders that I have handled have a great feel.

Nick Sisley has been a full-time freelance outdoor writer since 1969. He writes a regular shotgun column in Wildfowl magazine, Sporting Clays magazine, the Skeet Shooting Review and others. He’s authored eight books and penned thousands and thousands of magazine articles. He can be contacted at nicksisley@hotmail.com.

We’ve witnessed the revival of shotgun legends in recent years, but based on our field tests of the three new Veronas, none have combined the affordability, reliability and performance as these Italian workhorses.

The resurgence of cherished shotgun brands has been most active in the over $10,000 market.

In 1999 we saw a return of the glorious Holloway & Naughton marque, which brought the British legend that was started in the early 1890s back into circulation for some $90,000 in a bare-bones, in-the-white canvas of shotgun artisanship.

The stunning Victorian-era English Boswell was resurrected by writer, instructor and impresario, Chris Batha, with prices that begin in the neighborhood of $45,000.

And you could buy a reproduction of the legendary A.H. Fox shotgun with its entry-level price of $15,500. Or the same company, Connecticut Shotgun, will sell you a reproduction of another side-by-side great, the Winchester Model 21, also starting at $15,500.

When it comes to shotgun revivals you can’t escape the feeling that this is a club for trust-fund babies.

But Legacy Sports International has chosen a different path when it came to reintroducing the Verona pedigree to the American shotgun scene. The new Veronas now favor hunters and clays shooters who hanker after an Italian icon with a Main Street price tag.

Verona’s new over/under and side-by-sides embody the classical look-and-feel that have served generations of independent shotgun owners. The new Verona semi-automatics, meanwhile, pose a direct challenge to the inertia-driven shotguns from the other Italians, Benelli and Franchi

In short, the many qualities that made the first Veronas a go-to shotgun for thousands of American sportsmen have been inherited by the new Veronas.

The management team at Legacy Sports International jumped at the chance of resurrecting the beloved Italian brand that has quietly become a mainstay to thousands of American sportsmen.

“The original Veronas initially came into this country in the late 1990s and early in 2000,” explained Andy McCormick, the Vice President Marketing and Sales at Legacy Sports. “We discovered that the name was available again and when we trademarked it we decided to take the Verona back to its Italian roots. Everyone seemed to be happy that the Verona brand was coming back into the United States.”

Like their older siblings, the new Veronas are dependable shotguns for real people. They are fully capable of putting meat on the table year after year. This fine hunting tradition is in keeping with both the original Veronas and the folks at Legacy Sports who are serious hunters.

The new Verona over/unders come from the original factory in Italy operated by Fabbrica Armi Isidoro Rizzini, or F.A.I.R. as it’s known, in the Brescia region of Italy. Brescia is the cradle of the centuries-old, Italian gun industry.

Brescia is home to celebrated gunmakers such as Beretta, Perazzi, Fabbri, Fratelli Piottti, Rizzini and Abbiatico & Salvinelli.

It is here, in this exquisite valley, that F.A.I.R. got its start in 1971. F.A.I.R. now operates a 43,000-square-foot, state-of-the-art operation that houses everything from its own R&D group to CAD-CAM simulations to software-driven lathes that meet space-age tolerances.

The finishing can often end up in the skilled hands of a craftsman descended from the Medieval arms makers of the region.

Legacy Sports turned to another pillar of Brescia for the new semi-automatics. These guns are made by F. Lli Pietta. The company touts its expertise in making historical weapons such as Western-style revolvers, muzzleloaders and period rifles. It had an existing relationship with Legacy Sports, which clearly proved Pietta had the chops to make a modern semi-automatic with old-world TLC.

Legacy Sports turned to Fausti Stefano for its new side-by-side. The Brescia manufacturer has been in business since 1948 and sells shotguns all over the world. Its ultra-modern plant allows the company to produce quality shotguns at affordable prices with hand finishing by local artisans.

Although the Veronas are brand new shotguns, Legacy Sports has found a way to successfully mine a vein of expertise that stretches back hundreds of years.

In the spirit of continuity, Legacy Sports recruited Verona’s original gunsmith. As luck would have it, he had recently moved to Carson City, Nevada – a stone’s throw from Legacy Sports’ Reno operation.

“He was the Maytag repairman,” McCormick joked. “He did all the warranty work and maybe he’d get a cracked stock once in a while. That was about it.”

Having shot all three of the new Veronas, we can only surmise that not much will change for their gunsmith.

It was too early for bird season, but we did manage to get the guns out for skeet, 5 stand and sporting clays and they all felt rock-solid.

The Verona 401, 405 and 406 Semi-Autos

Verona’s inertia-operated semi-autos are available in 12 and 20 gauge, with either wood or synthetic stocks. The wood models come with 3-inch chambers while the synthetic models are also available with or 3½ inch chambers for 12-gauge only.

The wood versions will be available in three receiver finishes: blued, nickel and grey. We shot one in grey that had the traditional green Verona oval rendered in blue, and it was a handsome combination evocative of one of the most elegant and contemporary looking receivers in the shotgun universe, the Blaser F3.

Features:

¨ Chrome-lined barrel internally choked for steel shot

¨ 12-gauge barrel length of 28 inches; 20-gauge barrel length of 26 inches

¨ Brass sight on standard model; fiber optic on deluxe model

¨ Pivoted head bolt with integral double-charging lever and sleeve

¨ Oil-finished walnut stock and forend with checkering

¨ Black nylon recoil pad

¨ Patented locking forend

¨ 4 + 1 magazine capacity

¨ Length of pull 14¾ inches

The MSRP for the 12 gauge and 20-gauge Verona 401 varies between $1,199 and $1,250 depending on finish.

The Verona 405 is basically the Verona 401 with a black synthetic stock and forend and a blued receiver. The MSRP on the Verona will be forthcoming.

The Verona 406 is the model that handles 12-gauge, 3½ inch magnums. It’s finished with a black synthetic stock and forend and a blued receiver and has an MSRP of $1,199.

The Verona 501 and 702 Series Over/Unders

Named after the original over/under, the new Verona 501 Series field gun is distinguished by its nickel receiver. Standard features include:

¨ Enhanced walnut stocks with Scottish net-type checkering and oil finish

¨ Select fire single trigger

¨ Automatic ejectors

¨ Bottom locking bolt system on double trough

¨ Double sculptured receiver head

¨ Boxlock action

¨ Monobloc barrel construction

¨ 5 flush-mounted chokes (F, IM, M, IC and SK) and a choke key

¨ 28-inch chromed barrels with the X-CONE System (lengthened forcing cones) to reduce felt recoil

¨ Partially vented rib

¨ Fiber-optic front bead

¨ Solid lateral ribs

¨ Steel actions with automatic safety

¨ Ventilated rubber recoil pad

¨ Length of pull 14¾ inches

The Verona 501 Series is available with 28-inch barrels in 12, 20, 28 gauge and .410 models – all with an MSRP of $1,670.

A Verona 501 Series Combo set in 20/28 gauge has an MSRP of $2,599.

There is a higher grade Verona 702 Series, which is the one that we shot (more on that in a moment). It features more embellishment on the receiver, trigger guard and elsewhere on the gun. The Verona 702 Series has an MSRP of $1,780.

A great feature about both these guns is that they can handle 3-inch magnum loads, making them ideal for wingshooters with a flair for over/unders. The 12 gauge weighed in at seven pounds (with the smaller gauges getting progressively lighter), making it a nice compromise between basic heft for the recoil absorption of 3-inch magnums and easy lugability in the field.

The Verona 662 Side-by-Side

The 12-gauge version of Verona’s new 662 side-by-side upland shotgun packs the wallop of 3-inch magnums like its over/under brethren. That means, not only can you take this gun anywhere, but you’ll raise some eyebrows when you make shots that most would think impossible with a side-by-side that shooters assume is maxed out with 2¾ inch loads. In the vernacular of a muscle car, this baby is a sleeper.

Standard features of the Verona 662 side-by-side include:

¨ Boxlock compound-steel action

¨ Single trigger

¨ Color case-hardened receiver with fine laser engraving

¨ Reliable Anson-type forend mechanism

¨ 5 flush-mounted chokes (F, IM, M, IC and SK) and a choke key

¨ 28-inch barrels with concave rib (26-inch barrels on the 28 gauge)

¨ Oil-finished English-style walnut stocks and semi-beavertail forends, both checkered.

¨ Rubber recoil pad

¨ Weight of 6 pounds, 4 ounces

¨ Length of pull 14½ inches

The 12 gauge and 20 gauge models of the Verona 662 share an MSRP of $2,187. The 28-gauge model has an MSRP of $2,800.

Shooting the New Veronas

We had the unique opportunity to evaluate each of the new Veronas for some hard-core shooting. Since there’s not much bird shooting in the middle of June, we instead took the shotguns out for several rounds of sporting clays, 5 stand and skeet.

We’ll get to the individual shotguns in a moment, but uniformly they shared a very solid feel. Nothing wobbled when you closed the over/under and side-by-side. The barrels met the frame with an authoritative thud.

On the semi-automatic, the forend tightened down firmly. The joints between the receiver, spacer and stock were also tight.

Overall, the wood-to-metal finish on the shotguns was very good.

Shooting Impressions of the Verona 401 Semi-Auto

When Verona departed from the gas-operated actions of the previous 401s, Legacy Sports decided to take on the inertia champs, Benelli and Franchi.

We loaded 1? ounce Estate shells into the chamber and once we started shooting our first impression was that the Verona 401 seemed a little quieter than the Benellis. For an inertia-operated shotgun with a conventional wood stock we were also surprised at the low recoil.

The Verona 401 was deadly accurate, the slim receiver giving you a clear runway view along the rib and beyond the fiber-optic sight straight at the target. We found that this played well into intuitive shooting in terms of easily following the target to the desired point of impact.

With a smooth recoil pad and 14¾ inches length of pull, the Verona 401 came up without a hitch.

However, the Verona 401 felt a little nose-heavy to us, but so many shooters prefer that dynamic to maintain their swing we can only chalk it up to our own little subjective quirk.

The scalloped checkering and forend shape contributed to a sold and controlled grip. Likewise, the pistol grip of the stock was the perfect diameter so that our middle finger and thumb could meet as we held the shotgun. It also placed the front joint of our trigger finger comfortably on the trigger. The trigger pull was short and crisp, we figured coming in at around four pounds. Basically, the ergonomics of the Verona 401 were excellent.

Speaking of ergonomics, our favorite feature was the placement of the breech bolt release button. Most semi-autos have it on the right hand side, under the ejection port. The placement of the button on the Verona 401 is on the left side. Initially, this struck us as odd until we discovered that your right forefinger naturally finds it. We liked that a lot.

Shooting Impressions of the Verona 501-702

The gun we received from Legacy Sports was the more decorative 702. It featured 80% coverage of the floral engraving with gold inlaid birds on both sides and the bottom of the receiver. The rounded half-sideplates and floral hinge pins created a classical fascia that complemented the Schnabel forend.

While the walnut was in keeping with a shotgun for this price range, ours had a rich, dark hue with a stratification of tan and chocolate grains. The oil-finished stock and forend were perfectly matched.

The shotgun’s center of gravity felt exactly where your left hand held the forend – directly ahead of the receiver. This was ideal for shooting low gun, since the weight in your left hand facilitated you drawing the gun straight up and out until the gun was properly mounted on your shoulder and face.

At the same time, the angle and diameter of the pistol grip helped prevent you from see-sawing the gun – meaning that you lift it by the stock and consequently drop the muzzle.

Ultimately, the gun came up every time consistently for a smooth shot and follow-through.

We found the auto-safety to be intrusive for clays shooting, but remember as a field gun it would be essential. The shotgun had a single selective trigger and automatic ejectors, which should really be expected for shotgun in this price range.

The gun shot flat and true with unremarkable recoil for our 1? ounce loads.

All we can say is that we wished we could’ve gotten this shotgun out in the field with a bunch of birds. It would’ve been a heck of a lot of fun to shoot.

Shooting Impressions of the Verona 662

We much prefer interchangeable chokes to double triggers in our side-by-sides and so we approached the Verona 662 already endeared to it. The semi-beavertail forend that helped prevent you from burning your hands was icing on the cake (and we think that deep down inside those guys who shoot vintage side-by-sides with those splinter forends that barbecue your fingers would really like to step forward and give us a big huzzah).

We keep hearing about effete Europeans who make these impossible wingshooting shots with their 28 gauge and feel compelled to admonish us Americans for overkill (as in big ammo, big cars and big food). For those of the European school of shooting we politely say, Go away. The Verona 662 is clearly a side-by-side for American sportsmen who relish overkill.

Despite its straight English stock and case-colored receiver with fine floral engraving, the Verona 662 loaded up with 3-inch shells is a shotgun that you want to use on big, stubborn birds. Pheasants come to mind, and if you’re a pigeon shooter with a penchant for side-by-sides you should buy the Verona 662 now.

We savored shooting the Verona 662 for the sheer, raw power it exuded. At the same time, the gun never ran away from you; the straight stock and broad forend worked together for an empowering and accurate shooting experience.

Our only gripe with the Verona 662 was the lack of a selective trigger. Like the Verona 702, it also had an auto-safety that proved inconvenient during clays shooting. But part of that problem was our own enthusiasm in really wanting to shoot the heck out of the Verona 662.

Wrap Up

With the Verona 401 coming in at about $400 under the Benelli Legacy and a similar price as the Franchi I-12 Upland Hunter, it merits serious consideration for wood-finished, inertia-driven semi-autos.

The Benelli Legacy has more engraving while the Franchi I-12 Upland Hunter has a look that we think is bit more stodgy. The Benelli and Franchi are certainly celebrated for their reliability, but Verona’s own track record as a manufacturer of shotguns that go the distance certainly speaks to it own quality.

When it comes to the Verona 501-702, the price, quality and dependability pretty much put the guns in a class of their own. But does that mean you should buy the Verona a 501-702 on price alone? Chances are you are familiar with the most popular new over/unders in the $2,000 – $3,000 category. We believe the Verona 501-702 stands up for its workhorse virtues and classical looks – plus it will handle 3-inch magnum shells. From our perspective, that makes for a compelling package.

The Verona 662 has also carved out its own niche in the under $3,000 side-by-side market. Obviously, the Verona 662 is not for the breeks set. But with its 3-inch-shell capability, straight stock, interchangeable chokes and single trigger it would be hard to find a side-by-side that delivers more pure fun.

Irwin Greenstein is Publisher of Shotgun Life. You can reach him at letters@shotgunlife.com.

Useful resources:

Legacy Sports International/Verona Shotguns

{loadposition signup}

Join an elite group of readers who receive their FREE e-letter every week from Shotgun Life. These readers gain a competitive advantage from the valuable advice delivered directly to their inbox. You'll discover ways to improve your shooting, learn about the best new products and how to easily maintain your shotgun so it's always reliable. If you strive to be a better shooter, then our FREE e-letters are for you.

Shotgun Life is the first online magazine devoted to the great people who participate in the shotgun sports.

Our goal is to provide you with the best coverage in wing and clays shooting. That includes places to shoot, ways to improve your shooting and the latest new products. Everything you need to know about the shotgun sports is a mouse-click away.

Irwin Greenstein

Publisher

Shotgun Life

PO Box 6423

Thomasville, GA 31758

Phone: 229-236-1632