Shotgun Life in Gardone Val Trompia: Part 2, Perazzi

In late March and early April of 2017, Shotgun Life visited the legendary Gardone Val Trompia in the province of Brescia, which is the heart of Italy’s shotgun manufacturing. We spent time with shotgun makers Perazzi, Beretta, FAIR and F. illi Poli as well as master engravers Stephano Pedretti, Creative Art, Francesca Fracassi and Cesare Giovanelli. Here is Part 2 of our eight-part series called Shotgun Life in Gardone Val Trompia.

In late March and early April of 2017, Shotgun Life visited the legendary Gardone Val Trompia in the province of Brescia, which is the heart of Italy’s shotgun manufacturing. We spent time with shotgun makers Perazzi, Beretta, FAIR and F. illi Poli as well as master engravers Stephano Pedretti, Creative Art, Francesca Fracassi and Cesare Giovanelli. Here is Part 2 of our eight-part series called Shotgun Life in Gardone Val Trompia.

If you get the opportunity to visit with Mauro Perazzi at his eponymous shotgun factory in Italy’s Gardone Val Trompia, be advised to wear your running shoes. Much like the Olympic-winning shotguns he produces, Mr. Perazzi moves very fast.

He leads us through the plant floor of craftsmen’s work benches and precision CNC machinery –talking, pointing, pausing fleetingly to emphasize details – his own running shoes powering him across the immaculate concrete floor. You sense the workplace rhythm that fluctuates from high industrial RPMs to patient hand assemblage. Nevertheless, Mr. Perazzi’s winning speed is full-throttle. Yes, Perazzi is called the Ferrari of shotguns, and clearly Mr. Perazzi personifies the metaphor.

Mauro Perazzi explains the process for pressure testing its barrels using the machine behind him.

So it’s somewhat ironic as we race around the factory with Mr. Perazzi that his company’s 70 factory experts produce on a typical day only about seven shotguns – or some 1,500 each year.

That’s because nearly every Perazzi is bespoke to exact customer specifications − with a split of 80 percent target models and the balance devoted to hunting upland birds − mostly to clients in the U.S. and U.K. Barrel length, rib type, single or double trigger, over/under or side by side, measurements and figuring of the Turkish walnut, grip style, drop-out or fixed trigger group, matched pairs – the factory is configured and staffed for a high degree of product specificity. And although you’ll find new Perazzis on display at its 12 authorized American dealers, a made-to-order shotgun takes about four months to deliver.

“The entire gun is made here in the factory,” Mr. Perazzi explained. “It’s more expensive to do it this way, but it’s very important for us keep the quality.”

Craftsmen at their work benches hand-finishing Perazzi shotguns.

Shotgun production progresses from back to front in the 97,000 square-foot facility. There are 10 computer controlled CNC machines, each costing approximately $1 million, in the rear of the building and through its center. These machines shape the steel and wood and hammer-drill the barrels to extremely tight tolerances 24 hours per day, seven days per week. Moving toward the front, craftsmen solder the top and side ribs and barrels to monobloc.

Mauro Perazzi talks with one of the women who checkers the stocks and forends.

At the work benches in the front, Perazzis are hand assembled by specialists. Mr. Perazzi shows us a particular bench that belonged to his father when he started the company 53 years ago, and where the man who now runs the company also spent time learning his craft. Nearby, a cluster of 15 engravers give rise to a melodic tapping. Two women fastidiously checker the stocks and forends.

“The most important part of the process is the hand assembly, where the gun’s soul is born,” he said. “We are not interested in increasing production.”

Mauro Perazzi in his factory.

Shadowing Mr. Perazzi through the factory, our tour becomes a living history of the shotgun sports – a remarkable progression from timeless hand-wrought artisanship to modern digital manufacturing. The experience takes on considerable historical significance when you factor that between 1964 and 2016 Perazzi shooters have won 54 Olympic medals.

International competition is at the heart of Perazzi. On November 7, 2012, when Mr. Perazzi’s father Daniele passed away at 80 years old, the company he started had swept the London Olympics with 12 out of 15 medals, including four gold. Perazzi’s reputation for building exceptional competition shotguns reached a fevered pitch in the U.S. Californian Kim Rhode had earned a place in the history books as the first American to win a medal in five consecutive Olympics when she garnered the gold in Women’s Skeet at the 2012 Olympics with her Perazzi MX2000S.

Mauro Perazzi explains how the technician behind him uses light to help regulate a shotgun barrel.

If there was a definitive shotgun to best understand Daniele Perazzi it could very well be the MX8. It exemplified the Perazzi philosophy that germinated in 1957 when Daniele and a freshman engineer at Fiat named Ivo Fabbri partnered to research new procedures for building shotguns.

At that point, Mr. Perazzi’s own company was five years old. He had started it at age 20 to build premium sidelocks, capitalizing on his previous six-year apprenticeship at a local gun concern. The 20-year-old Mr. Perazzi had already revealed his ingenuity by inventing and patenting a single trigger that his company manufactured for the gun trade.

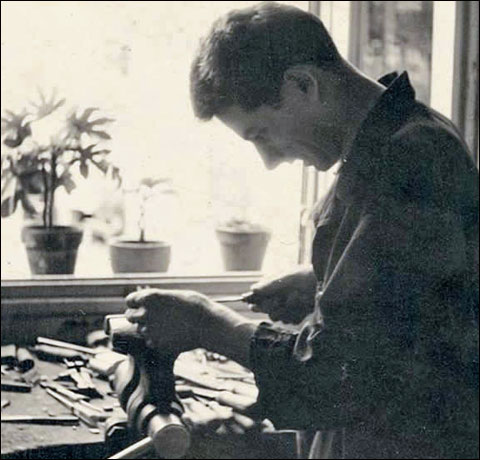

The early years of Daniele Perazzi at the bench of his fledgling company.

Perhaps the working-class pedigree of Mr. Perazzi and Mr. Fabbri influenced their mission, but the focus of their new venture, called Perazzi, was to modernize manufacturing practices employed by the “English best” gun makers in order to fabricate high-quality long guns affordable to most Italians.

An early assignment came from Italian sports shooter, Ennio Matterelli. Although he attained success with a Belgian Browning, he recruited the two Italian gunsmiths to render a trap gun for the 1964 Tokyo Olympics that would meet his rigorous specifications. With it, Mr. Matterrelli established a new record of 198/200 and won a gold medal.

A portion of the factory where Perazzi shotgun components are fitted and assembled.

A year later, Mr. Perazzi and Mr. Fabbri dissolved their partnership. Mr. Perazzi continued designing and building innovative competition trap and skeet guns.

With the departure of Mr. Fabbri, Mr. Matterelli became a partner in Perazzi. The men set their sights on the 1968 Olympics in Mexico City. The project inspired the designation MX8 (Mexico City 1968). The design goals for the new shotgun were strength, precision and balance. They vowed it would enable Mr. Matterelli to defend his title in the arduous heat and altitude of the forthcoming Olympic Games.

The Perazzi showroom in the lobby.

Although a gold medal eluded Mr. Matterelli, their work was not in vain. By the late 1960s Perazzi had become a revered name in Europe for state-of-the-art shotguns – a reputation that continues as the company celebrates its 60th anniversary this year.

From the factory floor, we go to the indoor patterning board. The space is long and dark. A glass partition separates us from the patterning board, which is an enormous slab of steel that both rotates and moves back and forth through the shooting corridor. A Perazzi is placed through a slot in the glass and fired. It’s here that the Perazzi barrels are regulated for accuracy before shipment.

A technician firing a Perazzi shotgun at the company’s patterning board checks barrel regulation.

Mr. Perazzi then takes us to the sauna-like drying room where Turkish walnut blanks are cured for three to four months. With about 8,000 stocks and forends warehoused, it would be tempting to change up for higher and higher grades as you became dazzled by the selections.

Part of Perazzi’s extensive inventory of Turkish walnut blanks for stocks and forends.

A few hours had passed quickly and we left the production facility for the sprawling showroom decorated with Perazzi’s flagship colors of red and white. The sales area would look familiar to anyone who has seen the Perazzi booth at the SHOT Show. We talked for a while and I thought our visit was ending, when Mr. Perazzi said he had one more thing to show us.

Perazzi’s gorgeous on-site clays range has hosted many Olympic champions.

We went through the front door, crossed the parking lot and entered a narrow gate that revealed a grassy, picture-perfect clays field bordered on the far end by cypress trees and beyond the green hills of Gardone Val Trompia. There were trap machines for ZZ birds, Olympic skeet and Olympic trap.

With a brilliant sky and sublime temperatures it was easy to imagine Perazzi Olympic medalists Cory Cogdell, Jessica Rossi, Hakan Dalby, Zheng Wang, Lance Bade, Kim Rhode, Juan Miguel Rodriguez, Dan Carlisle, Aleksey Alipov and Massimo Fabbriz all shooting here. I felt like we were on hallowed ground.

Irwin Greenstein is the publisher of Shotgun Life. You can reach him at contact@shotgunlife.com.

Read Shotgun Life in Gardone Val Trompia: Part 1, Fabbrica Armi Isidoro Rizzini (F.A.I.R.)

Useful resources:

Perazzi USA

1010 West 10th Street, Azusa, California 91702

(626) 334-1234

Irwin Greenstein is Publisher of Shotgun Life. Please send your comments to letters@shotgunlife.com.

Comments